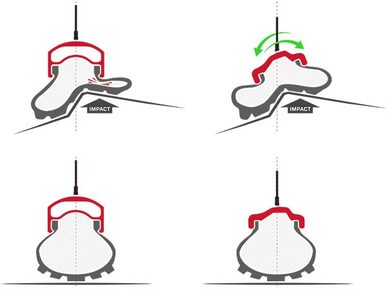

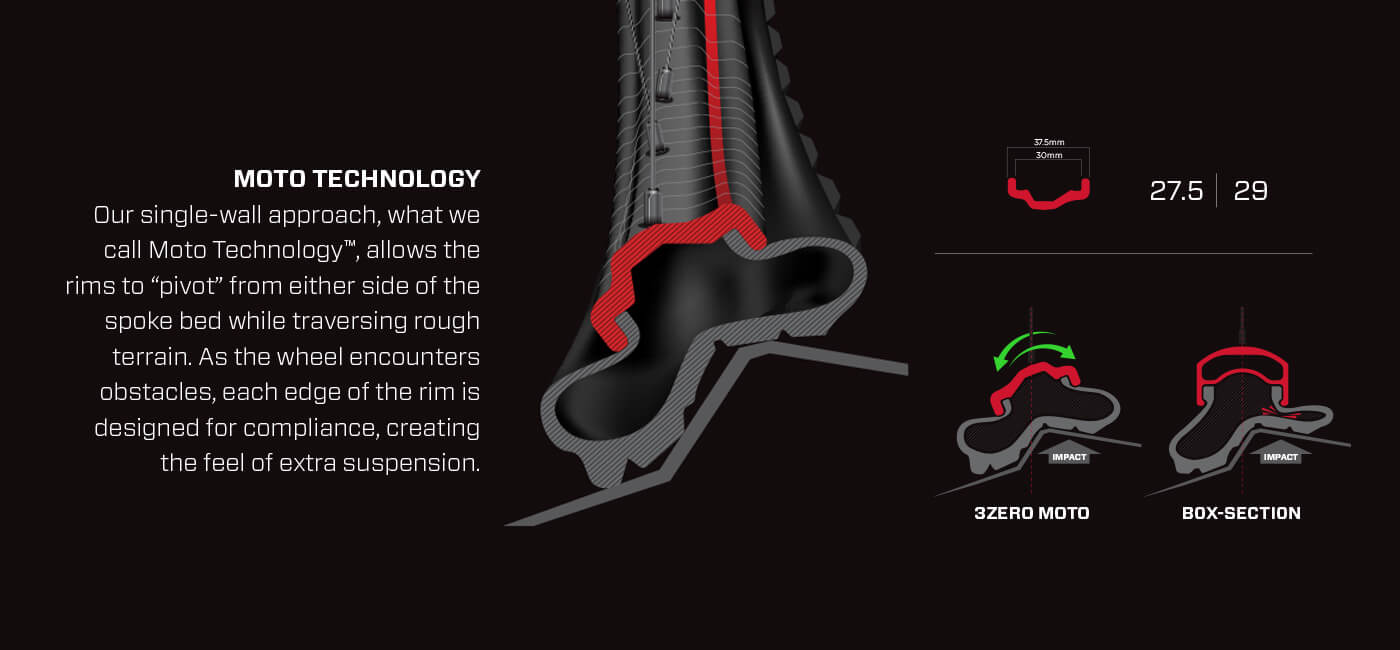

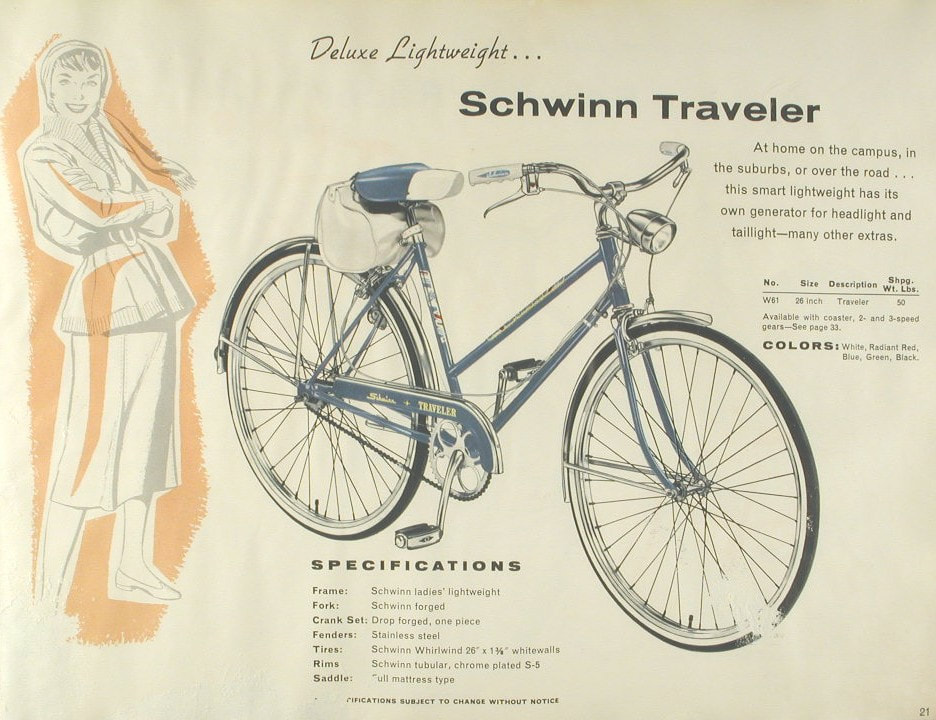

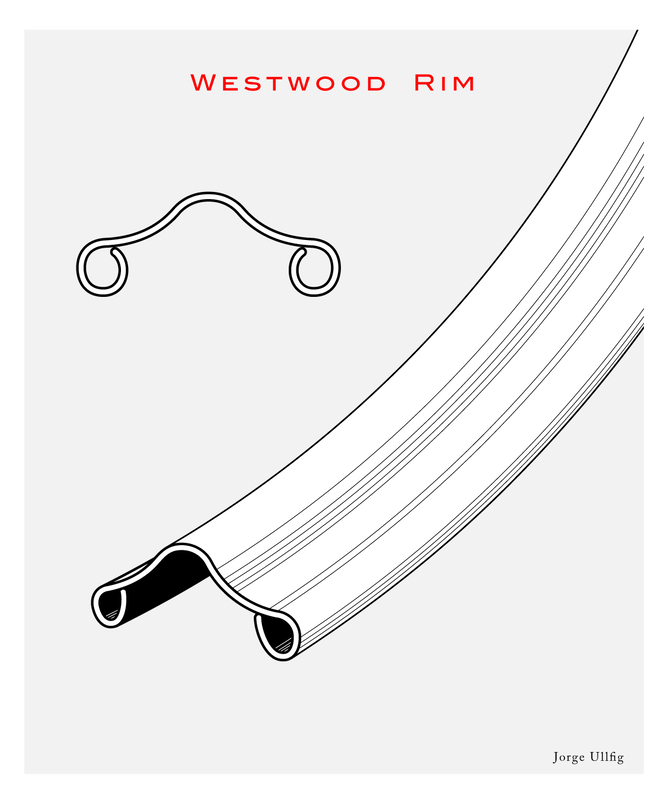

I got this in my inbox, and then laughed a bit, before having a deeper look. Zipp introduces a brand new ground-breaking technology, which looks really cool when you consider reinventing the wheel. I think they would have me believe that their new wide low profile rim is a completely new invention. They call it "3Zero Moto", and what it really is is the wheel from my 1956 three speed. OK, so it's not steel... What it also is, is a four year-old HED Carbon Fat Bike rim, or for that matter, any rolled rim from any shitty ten-speed circa 1960; Given, it's carbon. Here we see the very bleeding edge of marketing hyperbole, without a nod to it's forebears. Let’s take a closer peek, shall we? The revolutionary rim profile has a rolled or beaded edge, and no box section -- That's true. The breakthrough concept likely has a nicely locking bead for tubeless, and it perhaps costs way less to make than it's now obsolete analogous box-sectioned rim, because it's no longer necessary to accommodate flats for a rim brake, (shown below). Is it a break-through? In Fact, excepting the rust, and sharp edges, the Schwinn S-6 rim profile with rusty spokes poking through a dried up crusty rim strip is the Chrome-plated version of the new and revolutionary Zipp Concept called 3Zero Moto. The marketing goes on the mention the flex as being a bit more like suspension. Really?, it has travel? Perhaps not, but will you want to buy some? Sure. If you need a new wheel-set, then maybe these are for you. My guess is that they won’t do anything for you that brand “X” could not; But they are pretty carbon hoops laced to a nice hub. Groundbreaking? Nah!!, A placebo perhaps for people who need to believe in something new. But if you have a giant tire, soaking and smoothing the terrain, conforming and compressing under all fare of root and rock, is the wheel really changing the game? It seems the wheel is doing a fare bit of flexion, but the "Science" here is a bit of an over-reach.  Zipp Science: Lateral stiffness – In a sharp turn, the rim remains stiff, providing confidence that the wheel is firmly planted. Zipp’s wide hub flanges provide better spoke-bracing angles which help to increase the lateral stiffness. Torsional windup – When torque is applied to the rear hub when pedaling, you don’t want the spokes to create a spring-like flex sapping your wattage. Having 32 spokes at the right tensions keep the wheel constrained during windup, meaning the energy in your legs is efficiently transferred to your rear wheel. Radial Compliance – When you hit a rock, the system is designed to act as a shock absorber. Zipp’s MOTO Technology allows the rim to flex, which absorbs the impact energy and spreads it away from the impact zone for increased durability. In essence, more of the rim carries the load from the impact. “Ankle” Compliance – Imagine a runner rounding a sharp turn, the ankle naturally flexing to maintain grip as the runner leans. The rim can locally flex to stay parallel to the ground during cornering, which increases traction much like a human ankle. This ability to twist locally allows it to deflect during single bead impacts without the rider getting bounced off line. All of the above "Science" is lifted directly from Zipp's Webpage. I read it thoroughly, then looked for patent abstracts, and further details on the "Science" and found nothing with teeth. This is not to say that there is no "science" here to discuss, but if you observe the illustrations, and the rim is pivoting around the spokes which are centered to allow the Foot (rim) to roll below the "Ankle" (spoke bed) when pressured from a leveraged edge -- Then, like placing a pry bar beneath a heavy rock, you would of course expect the rock to lift on one side, and the other side to remain, somewhat as illustrated. So if that is truly the science, then It is true that this is nothing new, unless there is a breakthrough bearing point in the rim, some special active socket, which is not shown. If the "Science" (Ankle Compliance) is meant to illustrate tilt of the rim edge whilst the static fulcrum (pinned by the Spokes) remains level and; If the rim is flexing to give way to a large path obstacle, then the "Science" (Radial Compliance) is a twisting rim. This isn't illustrated well here. Their Illustration shows the rim profile as a constant, but tilting, not flexion, where the rim would contort. Like a truck's rear suspension, the Ankle Compliance is illustrated properly showing one edge lift whilst the other is lowered. I'm looking for the Science, but the illustration betrays the description. Ball and socket, ankle and foot?, or Compliant rim conforming to applied pressure from each side? Both perhaps? Either way, when I got my first BMX bike I longed for a set of wheels built up on ACS Z-Rims, which were glass composite flexy hoops, which because they sprang back, tended to keep shape in large drops and jumps, and not take the shape of the flat you hit... So I think that this is what Zipp have invented (reinvented). Sans the 4 cross lacing of a late 70's ACS Z-Rim. we have a bit of flex, owing to the properties of carbon. Great, I have these wheels, they came on my fat bike five years back. The steel version came on my Raleigh 3 Speed, and countless Schwinns, c.1965. Oh!, coincidentally the shallow cross-section profiles are similar from Zipp to Z-Rim to Schwinn, and further. I'm glad that we now have disc brakes and that the carbon layup is now simpler, and less costly. As far as science goes, we take a Z-Rim, and reduce the spoke count down the middle, and what we get is the next big thing. Reinventing the wheel is hard work.  Of course when every bike was a coaster brake, or even a rod brake there was no reason for a side profile to press a pad against. In that spirit basic rolled steel rim from Araya, Rigida, and Schwinn are roughly the same as Zipp's "Moto Technology"; even the Westwood has “Moto Technology”. The only way to form pliable steel into a hoop in the 50's was Moto technology. Image left, is an extruded aluminum hoop c.1995 likely a Mavic Open 4CD or some such, whereas the wider one on the right is rolled steel, c.1965, decidedly not a box design. The Schwinn rim on the right is a simple rolled steel hoop seems to possess Zipp's "3Zero Moto Technology". Wow, that was a throwback. A flaccid flexible hoop, that keeps the tire on, and prevents pinch-flats because it is so damn flexy that it follows the terrain, and has little bead to speak of. Man, that was simple. Inventing something new today seems to be as simple as re-naming it. Complaining about Zipp's new invention may contribute to a silly Moral Panic, but it is sometimes justifiable, to curb your enthusiasm when it's just a hoop with spokes. I suppose the new normal is to tell a story, and stand firm. Little fictions, like My Dad invented "Some cool Shit", but when my friends called me out on it, I looked like a fraud. When being disingenuous becomes the status quo, we all get to bull-shit each other unchecked, right? Standing on the shoulders of giants allows for a great view, doesn't it? Now you can merely look over the fence at your neighbor's rusting 3-Speed, spy the technology that you will now call your own. Throw a through axle and 12 gears on it, and you have a breakthrough, ‘Moto’! meh!... I Wish I had a patent on "3Zero Moto Technology", whatever that is, (3-Speed wheel technology now borders on steampunk). I suppose it doesn't matter much when I already have this technology on my vintage Schwinn. I hope nobody minds when I call my 3-Speed Moto Technology revelatory.

0 Comments

Leave a Reply. |

Age and Treachery will overcome youth and skill. Archives

January 2024

Categories |

RSS Feed

RSS Feed